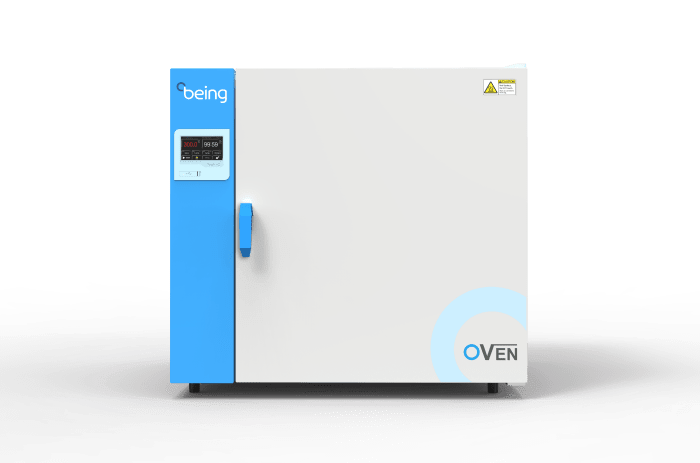

PRODUCT INFO

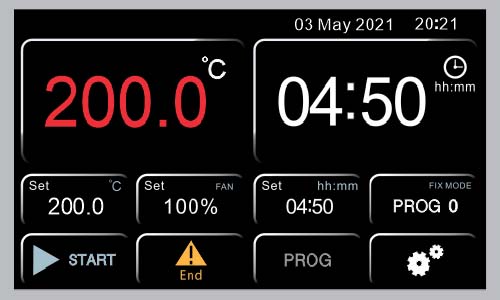

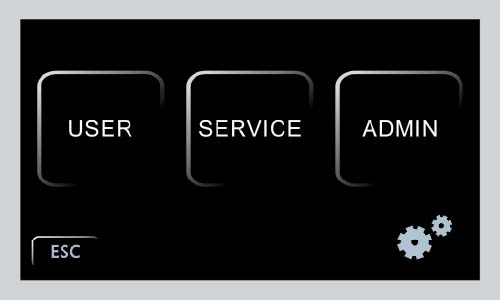

The BOF Forced-air Convection Drying Oven series distributes heat evenly inside the chamber with an integrated fan. This is ideal for drying protocols with very tight temperature requirements. The 4.3-inch touchscreen controller provides fast, accurate, and uniform heat displacement. Users can preset 8 periods and 8 steps for a total of 64 programs. Temperature, time and fan speed can be set and programmed at the same time. The doors are engineered with airtight sealing and inner chambers are designed with corrosion resistant stainless steel. Safety alarms are installed for – overtemperature, over current protection, and temperature deviation. These ovens provide excellent temperature stability and reproducibility for all your desired application needs ensuring maximum efficiency, safety, and ease of use.

Being Scientific BOF-Series

Performance and Features

-

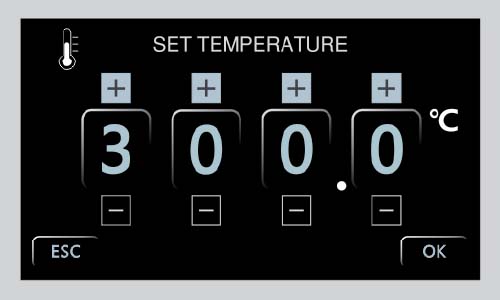

Temperature Range:Amb+10°C - 300°C .

-

P.I.D temperature controller provides accurate and reliable temperature control.

-

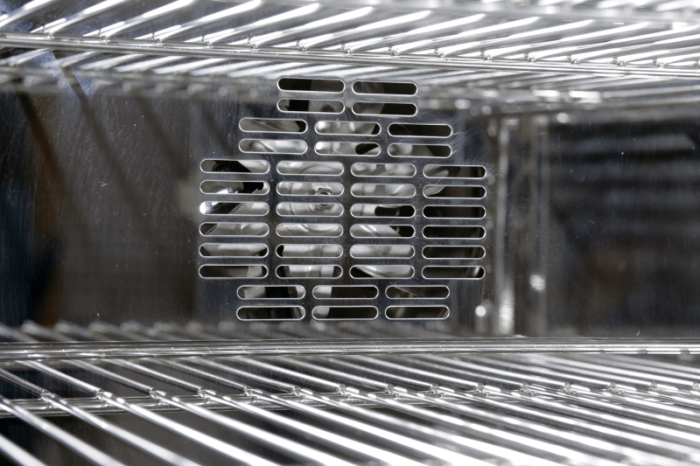

Mechanical convection facilitates hot air circulation.

-

Adjustable Exhaust Port/Vent.

-

Extended Life Silicone Rubber Gasket provides excellent sealing and long service life, but is easily replaced when the time for replacement is needed.

-

NEW color touchscreen controller.

-

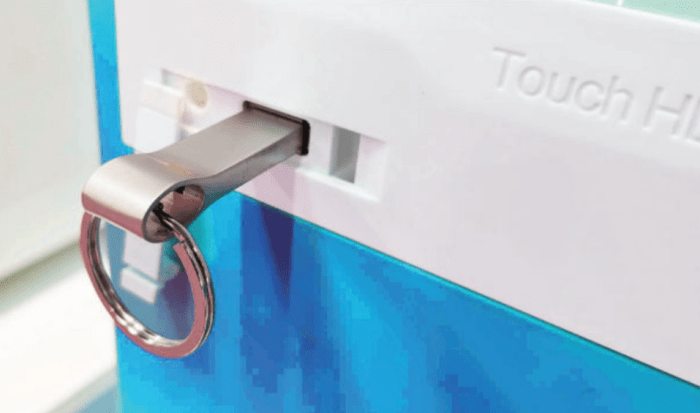

USB data collection port

Convenience

-

Variety of volumes to choose. ( 30 L to 400L).

-

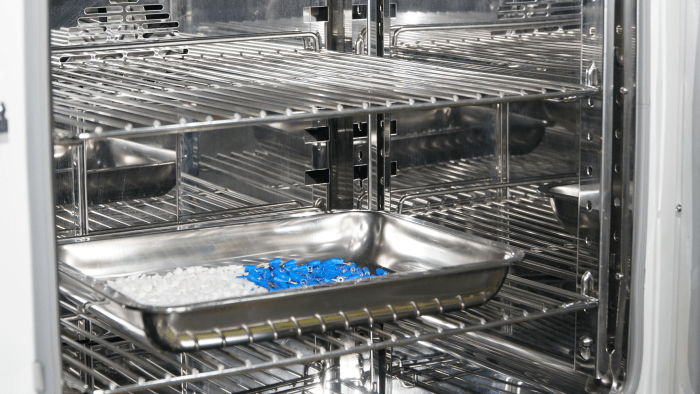

Inner chamber is made from corrosion-resistant mirror stainless steel.

-

Round curved inner angle is easy to clean.

-

Anti-skid shelf design, easy to operate by single hand.

Safety

-

Auto Start Feature after power loss/return.

-

Temperature deviation alarm.

-

Over temperature set point and shutdown with alarm.

-

Independent over temperature limit controller for added safety.

-

Over-current alarm and shutdown.

Stackable |

No |

|---|---|

Internal Volume |

1.1 cu ft (30 Liters) |

Temperature Range |

Ambient+18℉ to 572℉ Ambient+10℃ to 300℃ |

Temperature Stability |

±0.5℃ |

Uniformity at 100℃ |

±1.5 |

Heating Rate to 100℃ |

30 mins |

Display Resolution |

0.1 |

Maximum # of Shelves |

5 |

|

Test Hole |

Ø5mm |

# of Shelves |

2 |

Max. Load per Shelf |

44.1 lb / 20Kg |

Internal Dimension (WxHxD) |

12.6×12.6×11.6 (inch) 320×320×295 (mm) |

External Dimension (WxHxD) |

20.1×21.3×21.7 (inch) 510×540×550 (mm) |

Net Weight |

94.8 lb / 43Kg |

Timer (hh:mm) |

00:01 – 99:59 |

Electrical Requirement |

120V 60Hz |

|

Electrical Plug Type |

NEMA 5-15 |

Power Consumption |

1320W |

Catalog Number |

BO212030U |

Warranty |

2 years |

Certification | ETL |

Shelf Part Number |

P19267 |

The Chinese characters on the display can happen for a couple of reasons. One is someone was touching the screen during power up. Please download and follow the troubleshooting instructions.

No. However, the speed at which the oven reaches your desired setpoint can be controlled via the fan speed (BOF Series only), the adjustable exhaust port, and a multi-step program.

Fan speed (BOF Models only): The fan speed controls three elements of the oven: the volume of air being circulated in the chamber, the amount of ambient air being drawn into the chamber and over the heating element, and the baking time.

Operating the oven’s fan on high (100%) will speed up the reaching of the setpoint while running it on low (50%) will cause the oven to reach the setpoint more slowly. This is due to the volume of air circulating through the chamber and across the heater.

A high (100%) fan speed draws more ambient air into the chamber, while a low (50%) fan speed draws in less ambient air.

The fan speed also impacts the volume of air (humidity) leaving the oven through the adjustable exhaust port.

Adjustable exhaust port: Closing the vent will retain the humidity in the oven, causing a slower heat rise. It also reduces the number of heat exchanges by not allowing ambient air to be drawn into the oven’s chamber and over the heating element.

Opening the vent will allow the humidity to dissipate, speeding up the heating process, allowing more ambient air to be drawn into the chamber, and speeding up baking.

Multi-step programs: You can control how quickly you reach the desired setpoint by stepping from one temperature to another, holding for a period for the temperature to stabilize, and repeating this process until you reach the final (desired) setpoint.

No matter what fan speed you utilize, how open or closed the adjustable exhaust vent is, or whether you use a fixed-value or multi-step program, you will notice two things.

The oven starts heating rapidly, and as it closes in on the setpoint, the heating slows down so as not to overshoot the setpoint.

The larger the difference between chamber temperature and the setpoint, the faster the rise. The smaller the differential between chamber temperature and setpoint, the longer it takes to reach the setpoint. This is especially important to understand when using multistep programs.

For example, if the oven chamber is at ambient (20-25OC) and the setpoint is 200OC, the oven will ramp up faster than if, at the end of a step, the chamber temperature is at 150OC and the setpoint is 200OC.

Other factors impacting the setpoint reach and baking times include the number/volume of specimens, samples, or parts, their mass, the type(s) of materials in the specimens, samples, or parts, and their density inside the chamber. Density means they are packed close together or separated by some distance.

To optimize air circulation, we supply wire racks and recommend distributing specimens, samples, or parts evenly throughout the chamber.

No, and yes. On units with manufacturing (production) dates after January 1, 2023, the firmware can be updated by inserting a USB drive into the data collection port. Units built before January 1, 2023, CANNOT have the controller’s firmware updated.

No.

Yes.

BEING puts a product identification label above the power cord.

Yes.

Yes. We would need the unit's model and serial numbers if the certificate didn't come with your BEING instrument.

- BEING_BOFOperatingInstructions_V14_20250808.pdf

-

Operating & Troubleshooting Instructions

DOC_BEING-ChineseDisplayInstructions_V2_20230606.pdf - BEING-DryingVacuumOvenBrochure.pdf

- BEING_BOF-BONQuickStartGuide.pdf

| Packaging Materials | Paper box with pallet |

|---|---|

| Outside Dimensions (in./mm) | |

| 38 x 33 x 38 | |

| 980 x 830 x 960 | |

| Shipping Weight (lbs./kg) | |

| 220.0 | |

| 100.0 | |

| Freight Class | 125.0 |

| Packaging Materials | Paper box with pallet |

|---|---|

| Outside Dimensions (in./mm) | |

| 42 x 36 x 41 | |

| 1080 x 920 x 1050 | |

| Shipping Weight (lbs./kg) | |

| 286.0 | |

| 130.0 | |

| Freight Class | 125.0 |

| Packaging Materials | Paper box with pallet |

|---|---|

| Outside Dimensions (in./mm) | |

| 29 x 28 x 27 | |

| 740 x 720 x 700 | |

| Shipping Weight (lbs./kg) | |

| 123.2 | |

| 56.0 | |

| Freight Class | 100.0 |

| Packaging Materials | Paper box with pallet |

|---|---|

| Outside Dimensions (in./mm) | |

| 54 x 36 x 51 | |

| 1380 x 920 x 1300 | |

| Shipping Weight (lbs./kg) | |

| 517.0 | |

| 235.0 | |

| Freight Class | 100.0 |

| Packaging Materials | Paper box with pallet |

|---|---|

| Outside Dimensions (in./mm) | |

| 33 x 28 x 32 | |

| 850 x 720 x 810 | |

| Shipping Weight (lbs./kg) | |

| 147.4 | |

| 67.0 | |

| Freight Class | 110.0 |