PRODUCT INFO

In a vacuum drying oven, the thermal processes occur in an airtight chamber where a desired vacuum level is set using an external vacuum pump. With vacuum ovens, entire applications can take place under vacuum or in a controlled atmosphere through the introduction of an inert gas. Vacuum ovens can help in the prevention of surface reactions (such as oxidation), decontaminating samples (removing lubricants for example) as well as for speeding up the out gassing process. When determining the vacuum oven process, bear in mind that you will need the correctly sized pump to adhere to application requirements. This requires defining the appropriate chamber size, the level of vacuum desired, and how quickly you will need to reach that desired vacuum level.

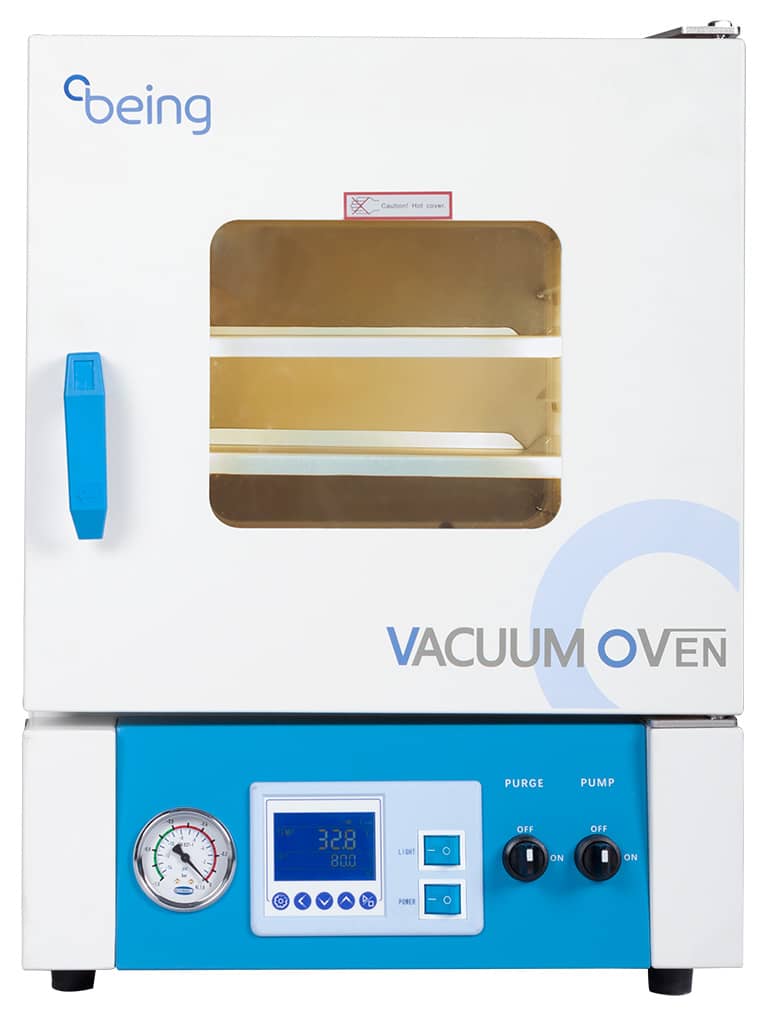

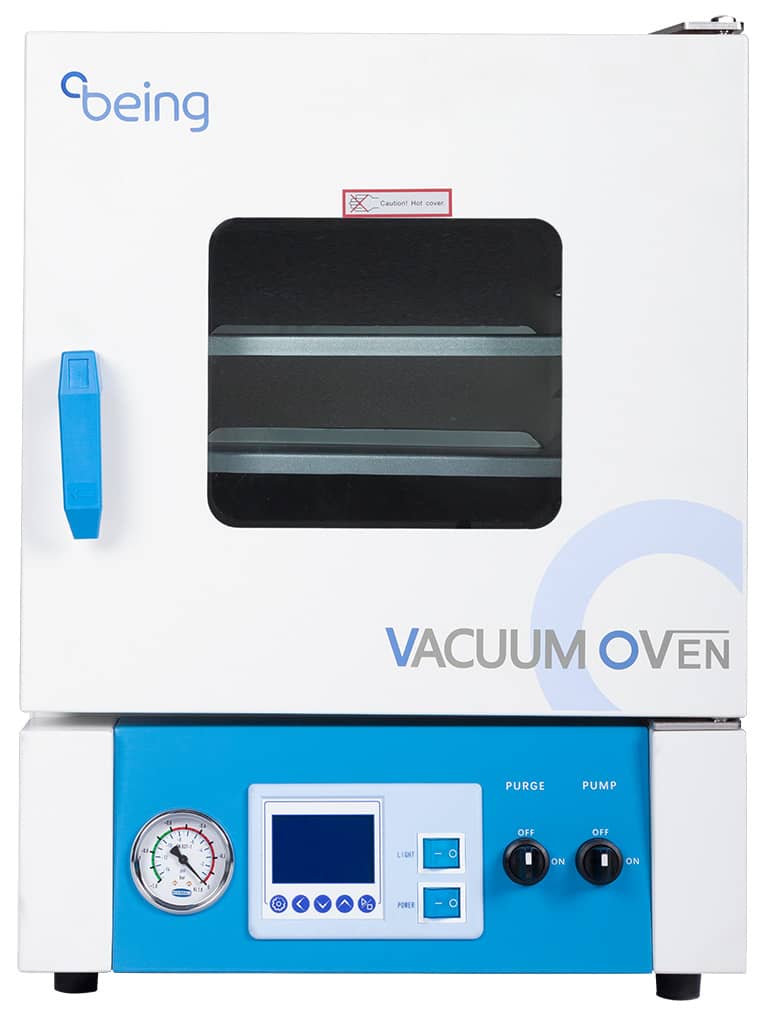

Being Scientific BOV-Series

Performance and Features

-

Temperature Range:Amb+10°C - 200°C .

-

P.I.D temperature controller provides accurate and reliable temperature control.

-

Vacuum Range: 0 - 0.1MPa. (limit vacuum 133Pa)

-

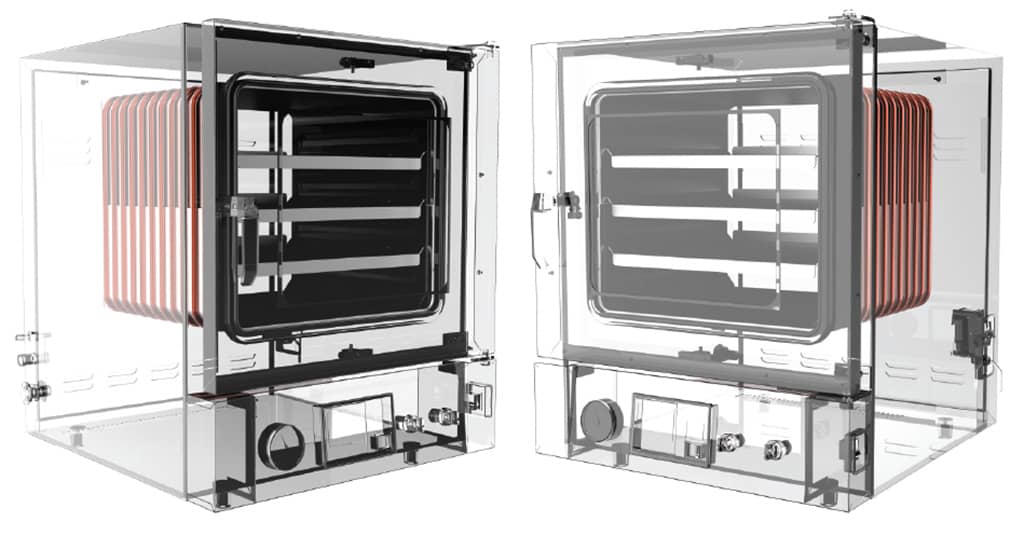

Bundled heating provides better temperature uniformity.

-

Inert gas interface for easy access to inert gases such as nitrogen.

-

LED lighting.

Convenience

-

Inner chamber is made from corrosion-resistant mirror stainless steel.

-

Built-in toughened glass door for clear observation of internal conditions.

-

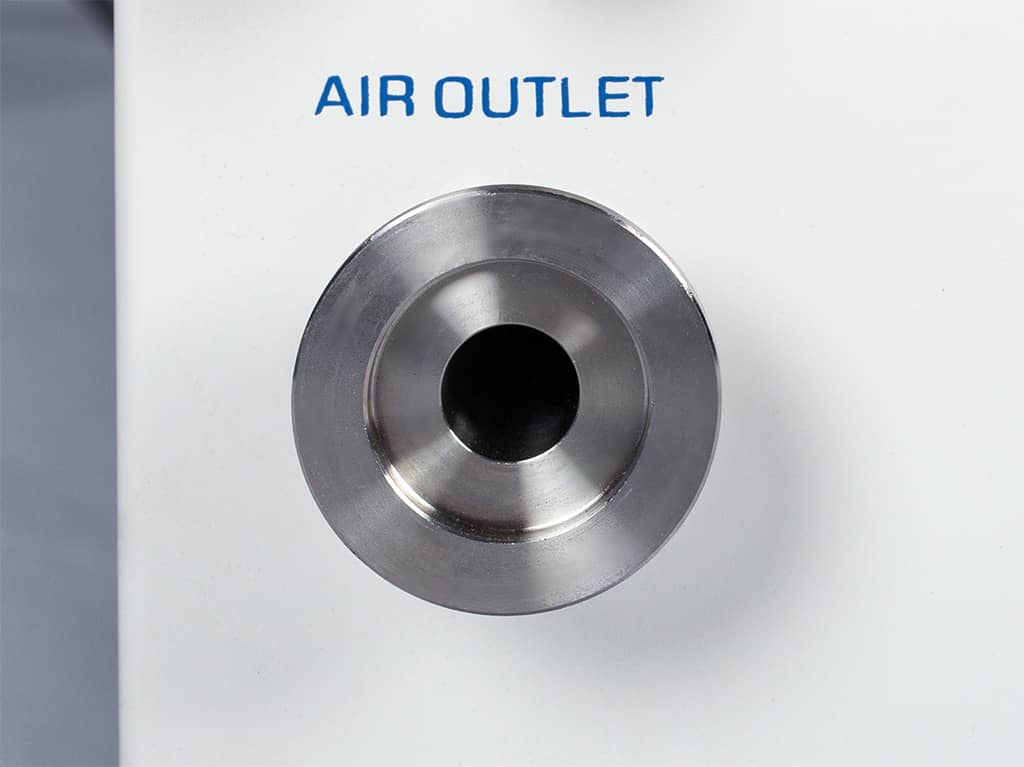

Independent vacuum interface and vents.

-

Equipped with solenoid valve to control vacuum degree and vacuum pump.

-

BOV-90 come with casters.

Safety & Peace of Mind

-

Temperature deviation alarm.

-

Over current protection alarm.

-

Over heat protection component protects your equipment. Will Cut off the heater automatically if the Temperature is out of control.

-

Independent overtemperature limit controller for added safety.

Chamber Volume (ft3 / L) |

0.9 / 24 |

|---|---|

Heating Type |

4-Sided Jacket Heating |

Temperature Range |

Ambient + 18oF to 392oF / Ambient + 10oC to 200oC |

Display Resolution |

0.1 |

Uniformity @100oC |

±1 (Shelf) |

Temperature Stability |

±0.5 |

Max. Degree of Vacuum |

133 Pa |

Work Chamber Material |

Sandblasted Stainless Steel |

Shelf & Rack Material |

Sandblasted Aluminum |

Door Seal |

Silicone |

Shelves (Std. / Max.) |

2 / 5 |

Shelf (W x D) (in / mm) |

11.4 x 11.0 |

Shelf Height Adjust. |

Yes |

Shelf Separation Height: (in / mm) |

NA |

Obs. Window Material |

Inner: Tempered Ballistic / Outer: Plexiglas® |

Interior Dimension (W×H×D) (in / mm) |

11.8 × 10.8 × 11.8 |

Exterior Dimension (W×H×D) (in / mm) |

17.5 × 24.4 × 22.8 |

Shelf Loading (lb / Kg) |

44.1 / 20 |

Net Weight (lb / Kg) |

132.3 / 60 |

Foot/Caster |

Foot |

Timer (hh:mm) |

00:01 – 99:59 |

Inert Gas / Air Inlet |

Yes |

Inlet Hose Barb (Ømm) |

8 |

Vacuum Port Type |

KF25 |

Electrical Requirement |

110V, 700W |

|

Electrical Plug Type |

NEMA 5-15 |

Elect. Outlet for Pump |

Yes |

Catalog Number |

BV15020U |

Shelf Part Number |

P19027 |

Vacuum Pump Recommendation

Vacuum Pump Type |

Dual Stage |

|---|---|

Pump Fitting Type |

KF25 Flange |

Degree of Vacuum (w/ ballast / w/o) (Torr) |

4 x 10-3 |

Flow rate (L/sec) |

2 |

Evac. Time (Minutes) |

1 |

No.

Yes.

BEING puts a product identification label above the power cord.

Yes.

Yes. We would need the unit's model and serial numbers if the certificate didn't come with your BEING instrument.

| Packaging Materials | Wooden Crate |

|---|---|

| Outside Dimensions (in./mm) | |

| 39 x 35 x 36 | |

| 983 x 890 x 912 | |

| Shipping Weight (lbs./kg) | |

| 0.0 | |

| 0.0 | |

| Freight Class | 0.0 |

| Packaging Materials | Wooden Crate |

|---|---|

| Outside Dimensions (in./mm) | |

| 25 x 26 x 33 | |

| 640 x 670 x 850 | |

| Shipping Weight (lbs./kg) | |

| 184.8 | |

| 84.0 | |

| Freight Class | 77.5 |

| Packaging Materials | Wooden Crate |

|---|---|

| Outside Dimensions (in./mm) | |

| 43 x 36 x 40 | |

| 1083 x 914 x 1012 | |

| Shipping Weight (lbs./kg) | |

| 0.0 | |

| 0.0 | |

| Freight Class | 0.0 |

| Packaging Materials | Wooden Crate |

|---|---|

| Outside Dimensions (in./mm) | |

| 30 x 30 x 37 | |

| 770 x 770 x 940 | |

| Shipping Weight (lbs./kg) | |

| 275.0 | |

| 125.0 | |

| Freight Class | 77.5 |

| Packaging Materials | Wooden Crate |

|---|---|

| Outside Dimensions (in./mm) | |

| 35 x 32 x 45 | |

| 900 x 810 x 1140 | |

| Shipping Weight (lbs./kg) | |

| 396.0 | |

| 180.0 | |

| Freight Class | 77.5 |